Automotive

Protection and reinforcement nettings

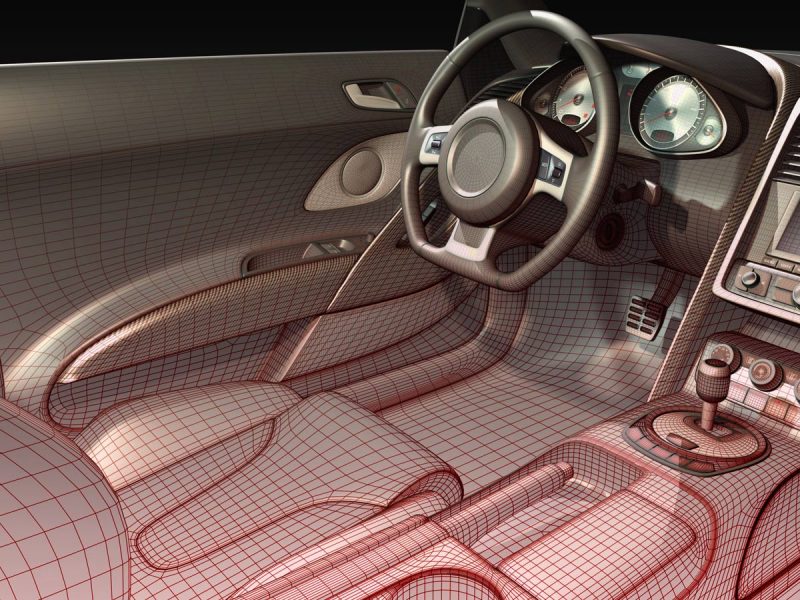

TENAX products find place in many different automotive components. Light weight netting used as support and reinforcement of industrial foams and textiles inside car seats, doors, dashboard and and carpets.

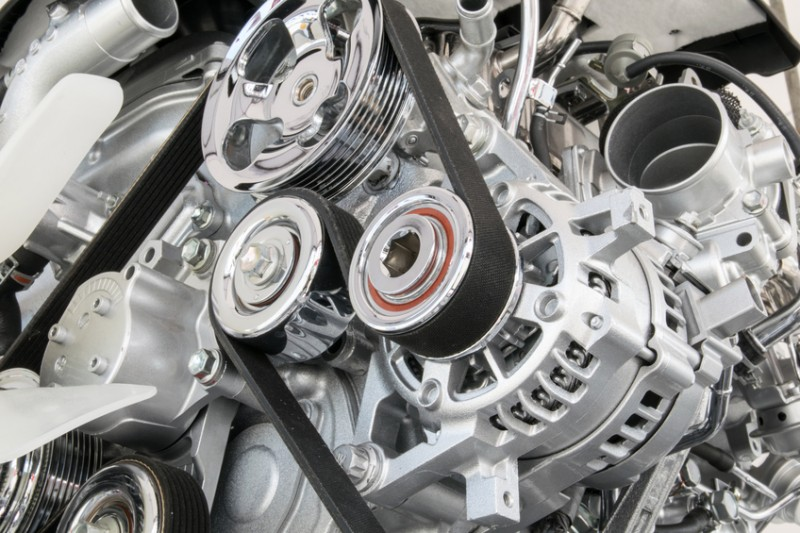

Pleating support and protective tubular nets used in automotive oil and air filters.

Raw materials

hPP – Homopolymer polypropylene

- Specific weight: 0.9-0.915 g/cm3 (56.19-57.12 lb/ft3)

- Melting temperature: 162-168°C (323.6-334.4°F)

- Tensile strength: 34-37 MPa

- Young’s modulus: 1200-2000 Pa

- Yield elongation: 5-10%

- Break elongation: 500-700%

- Working temperature: +0°C – +90°C (32°F – 194°F)

- Max working temperature (short period): +100°C (212°F)

Light material, resistant to chemical substances (as salts, acids and strong alkalis) and with a high mechanical strength. It is used for bi-oriented (stretched) products. Suitable for direct food contact.

cPP – copolymer polypropylene

- Specific weight: 0.895-0.9 g/cm3 (54.62-56.19 lb/ft3)

- Melting temperature: 135-168°C (275-334.4°F)

- Tensile strength: 25-30 MPa

- Young’s modulus: 1000 Pa

- Yield elongation: 5-10%

- Break elongation: >500%

- Working temperature: -20°C – 70°C (68°F – 158°F)

- Max working temperature (short period): +80°C (176°F)

Slightly softer and more resistant to high temperature than the homopolymer but with similar mechanical features. Suitable for direct food contact.

PA6 (Nylon) -Polyamide 6

- Specific weight: 1.12-1.14 g/cm3 (69.91-71.16 lb/ft3)

- Melting temperature: 220-225°C (428-437°F)

- Tensile strength: 80 MPa (dry) –55 MPa (wet)

- Break elongation: 20-40% (dry) – 100% (wet)

- Working temperature: -40°C – 105°C (-40 – 221°F)

- Max working temperature (short period): 170°C (338°F)

It is an advanced polymer able to stand high temperatures and direct contact with oil, grease, fuel and other solvents. It shows a low friction coefficient and is resistant to abrasion, shocks and fatigue.