Tenax: Since 1960

THE 60'S

- Extrusion head technology

- First extruded tubular netting

- Polyethylene diamond mesh

- Bi-oriented netting

TENAX develops modern extrusion head technology

At the beginning of the sixties, TENAX managed to significantly develop extrusion heads, increasing their dimensions from just 2 up to an impressive 20 inches. In this way TENAX gained world-wide supremacy with products that were totally innovative in mesh width, size, structural resistance and therefore also in their applications. One example of this is OLINET netting, that was designed for the harvesting of olives.

TENAX produced the first extruded tubular netting in polypropylene

TENAX has always had the characteristics of responding to market requests with products that are totally functional in terms of needs. A clear demonstration of this is extruded tubolar netting in polypropylene, a development that allowed TENAX to brilliantly fulfill many specific needs, starting with those of the food industry. TENAX nets for the packing of Bologna sausage-meat (Mortadella) quickly proved themselves to be indispensable product for use in salami factories.

TENAX utilised high-density polyethylene for fencing

In the mid-sixties TENAX was the world’s top company in the manufacture of rhomboidal mesh fencing in high-density polyethylene. The specific application field for such products widened to a potential that could not be envisaged before that time.

TENAX applies bi-oriented netting in the nursery-gardening field

Our developmental commitment aimed at the agricultural sector is rich with awards and products that have drastically revolutionised nursery-gardening production techniques. One of the most important being the HORTONOVA support net for flowers and vegetables. A decisive step forward from traditional systems or the use of metal supports

THE 70'S

- Extruded netting as an alternative to metal

TENAX offers bi-oriented extruded netting as an alternative to metal

The range of extruded fencing products was widened thanks to TENAX.

The original TENAX longitudinal and transversal stretching technology has made a fundamental contribution to this development, significantly increasing the resistance, strength and reliability of the netting, going so far as to achieve similar characteristics to metal netting. With the launch of its CINTOFLEX bi-oriented netting, TENAX introduced a new way of resolving fencing problems.

THE 80's

- Orange net

- Integral geogrids

- Geogrids for drainage

TENAX acquires world-wide fame with its orange netting for building.

The modern building site has become increasingly important for TENAX in its commitment to research and production. It is not by chance that the examples of supremacy that TENAX gained in the construction industry are just as important as those gained in the agricultural and geo-technical field. Its orange netting is an emblem of the Group’s continued collaboration with companies working in the construction industry, and it has become the symbol of open sites and work in progress.

TENAX creates an innovative line of integral geogrids

This new technological leap enriches the range of TENAX products, marking a new stage in the evolution of plastic netting. Overcoming the limitations of traditional welded, woven and punched grids, TENAX has in fact patented an innovative moulding and continuous expansion technology for the reinforcement and stabilization of soils.

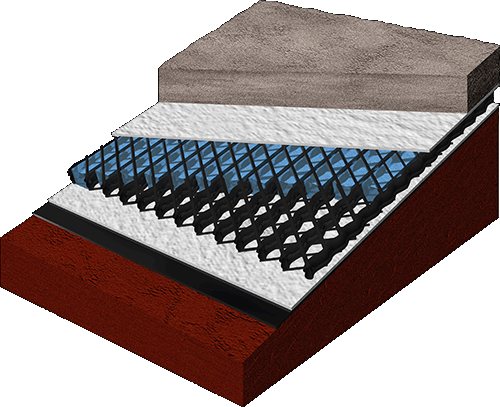

TENAX created a new standard in geogrids for drainage

In order to respond to the increasingly complex requirements of modern solid waste dumps, TNEAX was the first to create a drainage geogrid with a width up to 4 metres – double those on the market at that time. Thanks to the speed of their installation and the cost-reduction benefit they offered, these products became true reference standards in North America

THE 90's

- Civil engineering

TENAX introduces new civil engineering products

TENAX invests large amounts of resources and energy in research aimed at creating new products for the civil engineering and geotechnical field, in order to resolve specific ecological and environmental issues. For example, in order to resolve the problem of drainage in controlled waste sites, TENAX develops TENDRAIN, an innovative product made up of a three-dimensional structure with a drainage capacity that is ten times higher than any other netting.

DAL 2000

- Research & Development

- DP1 - RF1 - ECOQUADRA

The TENAX technological know-how is constantly offering new products and innovations

TENAX is also focused on gathering increasing knowledge of applications of its products and is adding new resources to support related sales. At the same time, the Group is continuing to invest in research and experimentation. It is continuing with scientific collaborations and synergies with those establishments that are concerned with environmental protection in particular, and is partecipating in projects aimed at creating products for ecologically-compatible progress.

TENAX innovation continues to be succesful in the market

Important new launches made since 2000 such as the innovative protective draining system DP1, the anti-fissuring polypropylene netting RF1 and Ecoquadra netting, made completely of recycled polymer, testifies to how TENAX innovation continues to be successful in the market.

DAL 2010

- Not just products, solutions:

Your Business is our Business, a marked focus on the customer

This is the concept that TENAX has been developing over recent years, using its own exclusive technological knowhow to serve an increasingly marked customer focus.

This translates into a refining of its ability to understand, and in some cases anticipate customer needs, and the desire to open up new channels of communication using its own marketing and technical/production experience.

In 2014 TENAX undergoes a major rebranding YOUR BUSINESS IS OUR BUSINESS. This is not an empty declaration of intent but the essence of what a TENAX partnership signifies.